Intro

Meat-processing businesses are quite energy-intensive factories. A freshness of chilled meat is strongly influenced by temperature. Inadequate storage, distribution and retail temperatures can lead to a significant reduction in shelf life and early spoilage of meat and meat products.

Temperature thus plays a leading role in the entire meat-processing chain and its management represents a constant challenge to maintain the safety and freshness of chilled fresh-meat until it reaches the final consumer. On the other side, the meat processing industry is a sector where cooling processes alone require an enormous amount of energy. Energy costs for many meat plants represent indeed the fourth highest operational cost (after raw materials, waste management and labor), as both electrical and thermal energy are consumed in wide range of processes (Fig.1).

Fig. 1

Meat carcasses are chilled immediately after post-mortem inspection at slaughter line and/or in slaughterhouse chilling rooms. The chilling process is aerobic as the carcasses are exposed to air circulation, to remove any further contamination and delay bacterial growth. Most often, after 24-96h of chilling at <7°C, the carcasses are usually moved to a boning/cutting room (deboning room, <12°C) where they are further cut into primary cuts, that are typically stored up to 6 weeks at 0-2°C in vacuum packs under anaerobic conditions. Packing, storage and distribution are the final stages where the product is packed to the correct specifications (use by date, description), stored, and sent for distribution to consumers.

There are many significant challenges in meat processing industry to undertake to become more energy-efficient and sustainable.

These are the goals of one of the Europe’s leading food processor company and largest beef processor in Ireland and UK. A dynamic, and multi-award-winning company with sixty years of food production industry experience and a well-earned reputation for quality, efficiency, traceability, and sustainability and with a particular focus on reducing environmental impact.

State of the art

For chilling carcass after slaughtering at their production site in York, food processor company’s existing refrigeration system comprised 250 kW of HFC plant which held around 1100kg of R434a (GWP= 3245). Decommissioning this system was then mandatory. In addition, reducing energy consumption and implementing a natural refrigeration system were the primary key points for the company.

Tecnofreddo was then selected as manufacturer of the refrigeration system for this new project. The coordination of this project, decommission and installation of the new system was carried out by an important partner of Tecnofreddo, Seward Refrigeration Limited, leading company specialized in the design, installation, service, and maintenance of industrial and commercial refrigeration systems in UK.

A tailor-made, eco-friendly solution

Seward Refrigeration was tasked with installing an environmentally friendly refrigeration system to meet end-user’s requirements. Tecnofreddo propane chiller was an ideal solution for this purpose.

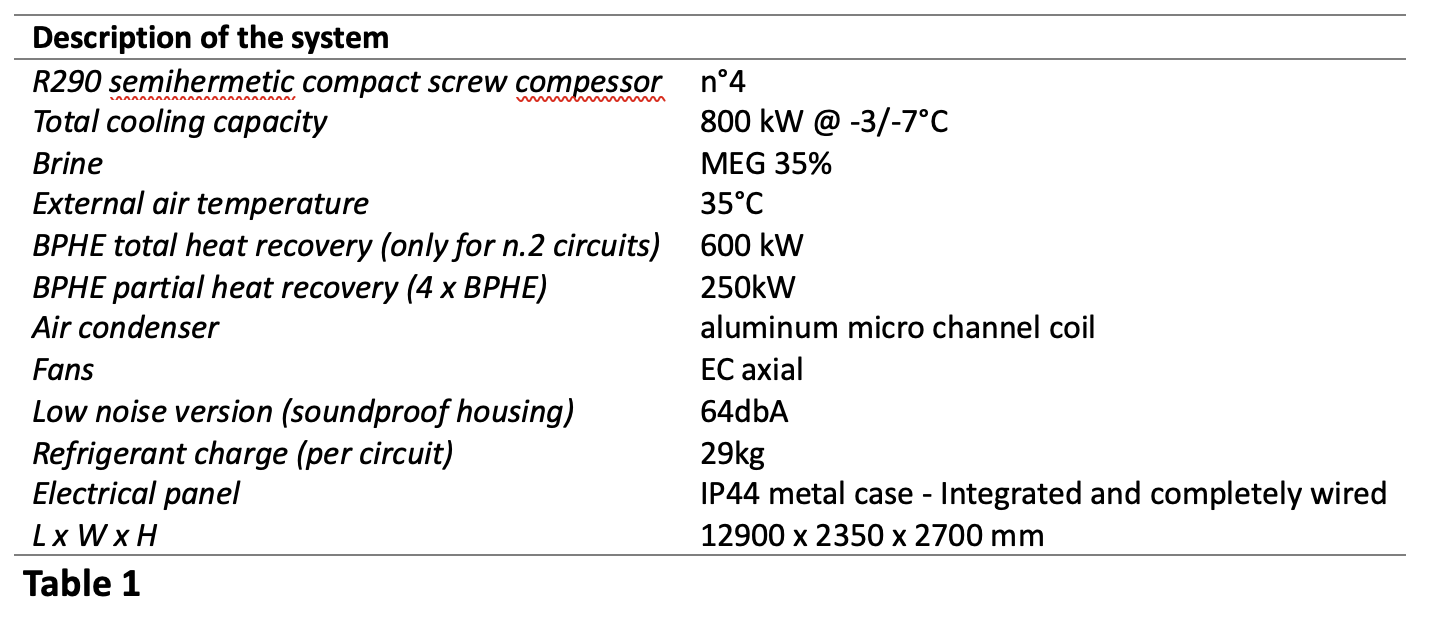

The highly- customized R290 chiller realized by Tecnofreddo, with 4 independent circuits provided 800kW of cooling capacity at -7°C. The R290 chiller is equipped with 6 x BPHE’s for heat recovery to supply a warm glycol for cooler defrosting, and to connect a heat pump in the future to generate hot water (Figure 2 – 4 and Table 1).

From the Tecnofreddo R290 chiller, Seward Refrigeration installed fully insulated stainless steel pipe work to provide -7°C DTX glycol to the new production areas on site. A 5000L buffer tank complete with run and standby glycol pumps was installed to ensure, under low loads, glycol DTX fluid at a constant temperature feeding the chilled areas.

New purpose-built beef chilling evaporators were installed in each area. Each area had two glycol valve stations, which were designed to control the DTX fluid through the coolers; they have been designed in such a way to reduce weight loss from the beef when chilling. Therefore, ensuring the weight loss is no more than 1.5%.

To defrost the evaporators on site, DTX glycol was pumped though de-superheaters on the Tecnofreddo R290 chiller back into a small 1500L storage tank, run and standby glycol pumps on all circuits. This warm DTX glycol is then used as free heat to defrost all the evaporators on site. The new refrigeration system is all controlled Via RDM controllers and a remote dial up available to provide immediate support to the client.

Conclusion

Once commissioned the new propane/glycol system and the Tecnofreddo chiller, the end-user was able to carry on with production on the new system, while decommissioning and removing the old 250kw HFC system from site. Another 250kW onto the chiller will be installed soon and the current HFC systems removed. The end-user will then proceed to remove all its HFC equipment from site over the next couple of years, so that all the refrigeration on site will eventually go on to the new glycol/propane system.

Among the challenges of sustainable management of meat production, the crucial topic in the design of the entire plant was also to improve the energy efficiency of the production processes, which will consequently affect the reduction of greenhouse gas emissions.

The reduction of greenhouse gas emissions is a key objective for the customer, who is always looking to drive forward through innovation and new initiatives. Prioritizing sustainability and recognizing the impact of the measures in place across processing sites, required an innovative and efficient solution, and Tecnofreddo – together with Seward Refrigeration – provided an efficient, sustainable, and innovative solution capable of creating high added value to the meat-processing sector with the lowest environmental impact.