Tecnofreddo S.r.l has developed a bespoke project for an important company in Trentino that produces to sell South-Tyrolean organic specialties in Italy and abroad. The products are all made with carefully selected raw materials that are subsequently frozen through an automatic process. Today, more than ever, in the food sector, the preservation of frozen food products requires efficient, reliable, but above all, eco-sustainable refrigeration systems. This is why the company has relied on the experience of Tecnofreddo, which has always been committed to the development of systems with low environmental impact and high energy efficiency.

A new eco-friendly refrigeration system

The company produces frozen food typical of Trentino region for catering, wholesale and retail companies as well to GDO distribution chains all over the world. Thanks to the quality of its products and the increase of demands, the company decided to expand its original structure. The design of the multi-store factory foresaw new production areas dedicated to the various processes, and in particular: a new low-temperature cold room (-28/-32°C) for the vertical storage of pallets on drive-in (10 levels) with loading/unloading automatism; a low temperature pre-cold room (-25 ° C) for the inlet/outlet storage of the finished product; a loading and shipping area with three points to dock the vehicles. The main focus was however to have a new eco-sustainable refrigeration system with a high coefficient of performance and a low energy profile.

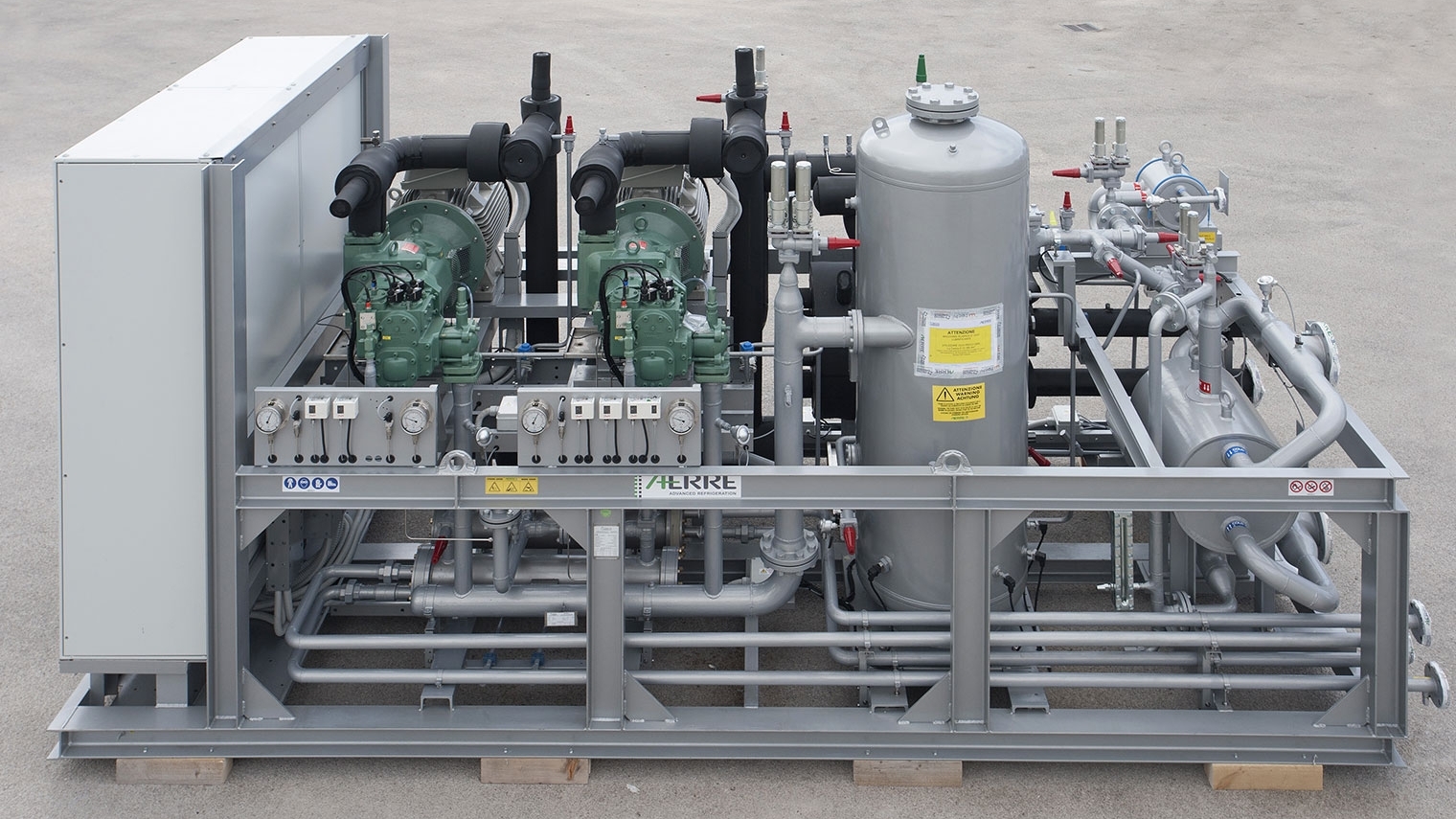

The solution: a natural brine chiller

In order to satisfy its customer needs, Tecnofreddo has realized a liquid cooler on an industrial skid and two condensing refrigerating units on a commercial skid, both for indoor installation. The systems use ammonia R717 and R744 (CO2), respectively, two natural refrigerants that respect the environment in terms of global warming and have no impact on ozone layer. The brine chiller with a cooling capacity of 400 kW produces water, in a glycol solution, at a temperature of -8 ° C. The chiller is equipped with two open-type double-screw compressors, a combined flooded S&P evaporator fed by means of a high-pressure float expansion valve, a plate desuperheater, a plate condenser and two S&T oil coolers. The two sub-critical CO2 units provide a cooling capacity of 21 kW and 118 kW, at an evaporation temperature of -35 °C. Both units are equipped with alternative semi-hermetic compressors; the condensation, with glycol solution at -8 ° C, is realized by a plate heat exchanger. Additionally, the brine chiller is equipped with two IE3 electric motors, each managed by an inverter: this consents to optimize the operating limits of the compressors with a significant reduction in terms of electrical consumption.

An easy-to-use system

For each unit Tecnofreddo has specifically developed and realized, within the electrical panel on board of the machine, a dedicated software for the Siemens PLC. Its management is possible, in an easy and intuitive way, thanks to the interaction and three-dimensional visualization of the various components of the brine chiller and CO2 refrigerating units.